In the world of 3D printing, the magic doesn’t stop once the printer finishes its job. Oh no, that’s just the beginning of a thrilling journey known as post-processing. Think of it as the final brushstroke on a masterpiece or the cherry on top of a sundae. Without it, your 3D printed creations might look more like abstract art than the sleek designs you envisioned.

Table of Contents

ToggleOverview of 3D Printing Post Processing

Post-processing in 3D printing serves a critical role in achieving not just aesthetics but mechanical properties too. Various techniques aim to enhance the surface quality and durability of printed objects. Techniques often include sanding, painting, and coating, each promoting a specific finish and function.

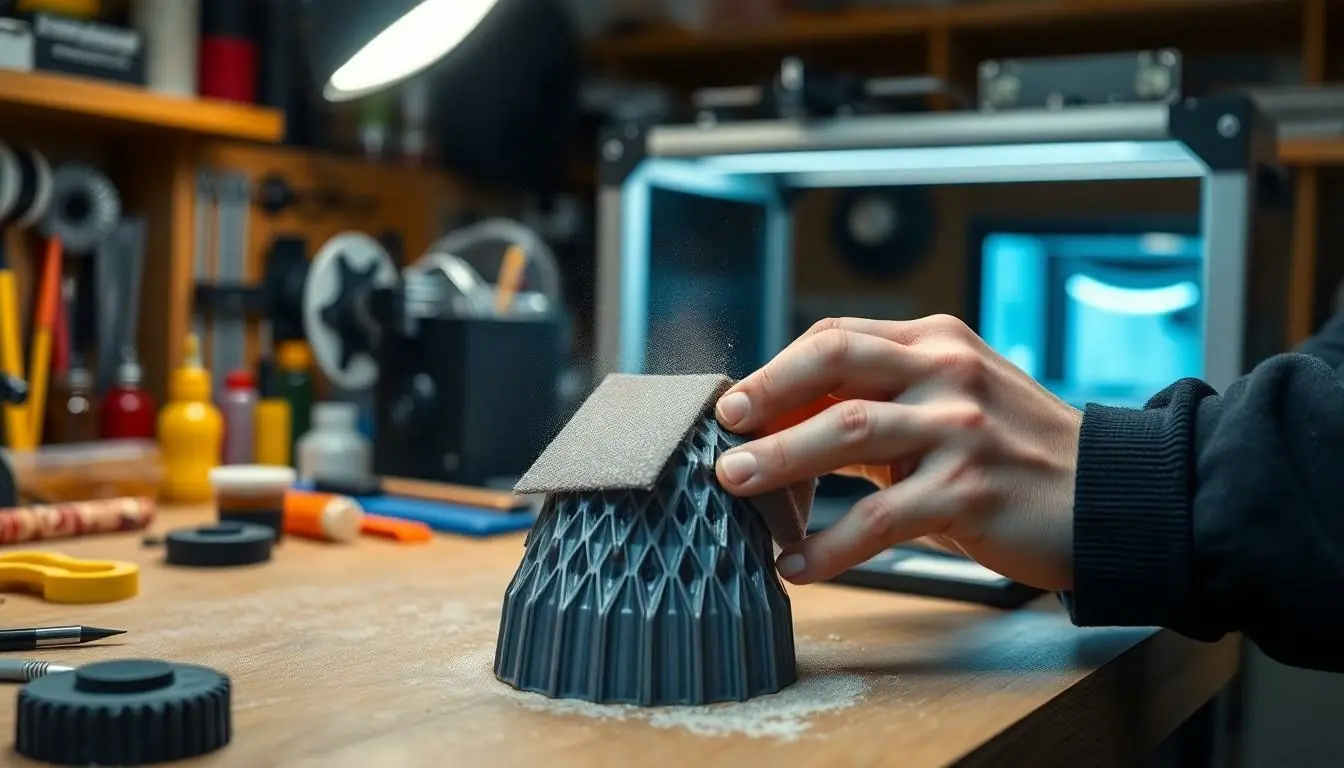

Sanding reduces visible layer lines, creating a smoother surface for parts. This process improves the visual appeal and enhances adhesion for subsequent painting. Painting, in turn, provides a layer of color and protection, allowing creators to personalize their prints. Coating options, like resin or varnish, add an extra layer of durability and often enhance glossiness.

Methods in post-processing are numerous. For instance, vapor smoothing utilizes solvents to refine surfaces on materials like ABS, yielding a polished appearance. Similarly, chemical baths effectively clean and prepare surfaces for other applications. Each method feeds into the project’s overall success, transforming raw prints into finished products.

Time considerations often dictate the extent of post-processing. Rushing through these steps can lead to compromised quality. Careful deliberation improves the final results, aligning them with specific project objectives. Understanding these processes empowers creators to maximize the potential of their 3D prints.

Finishing techniques differ according to the print material too. For example, PLA responds well to sanding and paint, while nylon may benefit more from vapor smoothing. Prioritizing the right methods based on material helps ensure the best outcomes.

Common Post Processing Techniques

Post-processing techniques enhance the quality and appearance of 3D printed objects. Various methods exist, with each serving a unique purpose.

Cleaning and Removal of Support Structures

Removing support structures is vital for achieving clean and presentable prints. First, careful assessment of the model determines the best removal method. Manual removal, involving tools like pliers or knives, helps eliminate supports without damaging the model. Alternatively, using water-soluble supports simplifies this process; simply soak the print in water to dissolve the supports. Cleaning the print afterward ensures a smooth surface, free from debris. Effective removal enhances the visual appeal and prepares the print for additional finishing processes.

Smoothing and Surface Finishing

Smoothing techniques refine the surface of 3D prints, contributing to a polished look. One popular method involves sanding, which reduces layer lines and imperfections. Using different grits of sandpaper allows for gradual smoothing, transitioning from rough to fine. Vapor smoothing serves as another option, where solvents are applied to create a glossy finish. This technique works particularly well with materials like ABS. Paint provides an additional layer of customization; it not only adds color but also offers protection. Applying coatings like resin further enhances durability and shine, giving prints a professional feel.

Advanced Post Processing Methods

Advanced post-processing techniques significantly enhance 3D printed items, offering a refined finish and improved durability. Chemical smoothing and painting or coating represent two effective methods in this process.

Chemical Smoothing

Chemical smoothing employs solvents to refine surfaces of printed models. Specific materials, like ABS, react favorably to acetone vapor, yielding a glossy finish. This method reduces visible layer lines and enhances the overall aesthetic. Users must exercise caution, as improper handling of chemicals poses health risks. Effective application requires an enclosed space to safely contain vapors, ensuring optimal results. Ultimately, chemical smoothing transforms rough textures into smooth surfaces, elevating the quality of finished products.

Painting and Coating

Painting and coating add color, protection, and aesthetic appeal to 3D prints. Various options exist, including acrylic paints, enamel paints, and specialized coatings. Applying a primer before paint maximizes adhesion and improves surface appearance. Coatings, such as varnishes or epoxy resins, enhance durability and provide a glossy finish. Each layer contributes to the final look, offering opportunities for customization. Attention to drying times and application techniques ensures a professional outcome, maximizing visual impact and safeguarding the printed item from environmental factors.

Benefits of 3D Printing Post Processing

Improved surface quality significantly enhances the visual appeal of 3D printed items. Smoother finishes emerge through techniques like sanding and vapor smoothing, which reduce layer visibility. This attention to detail results in a more polished product that meets higher aesthetic expectations.

Enhanced durability is another key advantage of post-processing. Coatings such as resin or varnish not only protect printed objects but also contribute to their longevity. These protective layers help resist wear and tear, ensuring that the final product withstands use over time.

Customization options expand through post-processing techniques. Painting allows creators to add unique colors and designs, catering to individual preferences. This personalization transforms standard prints into distinctive products, making them stand out in a competitive market.

Cost-effective improvements arise through strategic post-processing choices. Although initial investments may seem high, these finishing touches often elevate the perceived value of prints. Higher-quality products can justify premium prices, ultimately leading to better returns on investment.

Time invested in post-processing directly correlates with the final outcome. Rushing these steps may compromise both appearance and performance. Prioritizing quality over speed ensures that every project fulfills its intended purpose with precision.

Post-processing also allows for compatibility with various materials. For instance, PLA prints benefit from sanding and painting, while nylon requires particular techniques like vapor smoothing. Understanding material properties aids in selecting the most effective post-processing methods, optimizing each project for success.

Advanced methods further expand post-processing benefits. Chemical smoothing techniques, especially with materials like ABS, create glossy finishes that enhance visual appeal. While safety precautions remain vital, mastering these techniques empowers creators to achieve professional results consistently.

Challenges and Considerations

Post-processing in 3D printing presents various challenges that creators must navigate. Time management emerges as a critical factor; spending too little time on post-processing can lead to disappointing results. Careful evaluation of the print material influences the choice of techniques as different materials require specific approaches.

Safety concerns often arise with advanced methods. Using chemicals for smoothing necessitates caution due to health risks associated with exposure. Proper ventilation becomes essential when employing solvent-based techniques, particularly with materials like ABS.

Material compatibility poses its own set of challenges. PLA, for instance, responds well to sanding and painting, while nylon benefits from vapor smoothing. Each technique requires an understanding of the unique properties of the material to achieve optimal results.

Cost implications typically affect decisions. Investing in quality post-processing tools can lead to superior finishes that justify their expense. Time spent in this phase translates to potential financial gains through higher-quality end products.

Support removal needs careful attention. Choosing between manual tools or water-soluble supports requires analysis of the model and print settings. Ensuring clean and presentable prints that meet project goals dictates the choice of removal method.

Customization options expand the scope of post-processing but bring complexity. Balancing aesthetics with durability often requires experimentation with various paints and coatings. Each layer added contributes not only to visual appeal but also to the overall lifespan of the printed item.

Focusing on these challenges allows creators to enhance their 3D printing projects effectively. Understanding these considerations will lead to better outcomes that fulfill both functional and aesthetic objectives.

Post-processing is an essential step in the 3D printing journey that transforms a printed object into a polished masterpiece. By carefully selecting and applying techniques like sanding, painting, and coating, creators can significantly enhance the surface quality and durability of their prints.

Investing time in post-processing not only improves aesthetics but also increases the lifespan of the final product. With the right approach, creators can unlock the full potential of their 3D prints, ensuring they meet both functional and visual expectations. Mastering these techniques leads to higher quality results that can elevate any project.