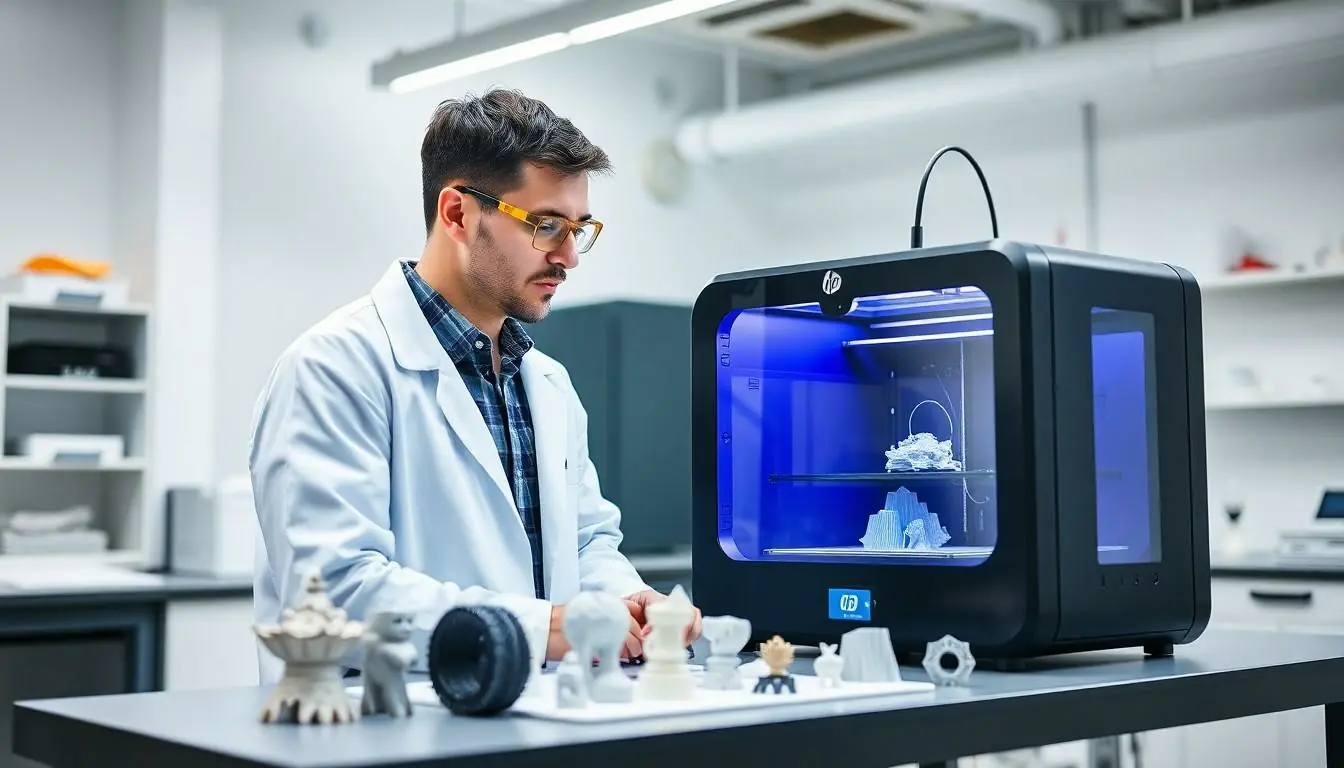

In a world where creativity knows no bounds, HP 3D printing is the superhero every designer and engineer didn’t know they needed. Imagine turning your wildest ideas into reality faster than you can say “additive manufacturing.” With HP’s cutting-edge technology, it’s not just about printing; it’s about revolutionizing how products are made.

Gone are the days of waiting weeks for prototypes. HP 3D printing brings speed and precision to the table, making it the go-to solution for businesses eager to stay ahead. Whether it’s creating intricate designs or functional parts, this technology makes it all possible, and let’s face it, who wouldn’t want to be the office wizard conjuring up amazing creations? Get ready to explore the magic of HP 3D printing and unlock a world where imagination meets innovation.

Table of Contents

ToggleOverview of HP 3D Printing

HP 3D printing represents a significant advancement in manufacturing and design technologies. This innovation streamlines the prototyping process, enabling businesses to bring ideas to life quickly and efficiently.

History and Evolution

HP began exploring 3D printing technology in the early 2000s. In 2014, HP unveiled Multi Jet Fusion, a groundbreaking technology that significantly changed additive manufacturing. This technology focuses on speed and quality, allowing for rapid production of complex parts. Over the years, HP expanded its 3D printing portfolio to include various materials and applications, catering to industries such as automotive, healthcare, and aerospace. Continuous investment in R&D has driven innovations in the field, reinforcing HP’s position as a leader in 3D printing solutions.

Key Technologies

Multi Jet Fusion serves as a cornerstone of HP’s 3D printing capabilities. This technology enables the production of functional parts through precise material deposition. HP’s 3D printers utilize high-speed processing to create intricate designs with excellent detail. Materials like nylon, thermoplastics, and elastomers enhance versatility in applications. Additionally, the use of advanced software ensures optimal printing performance and design integration. Overall, these key technologies facilitate rapid prototyping and production, meeting diverse business needs across various sectors.

Applications of HP 3D Printing

HP 3D printing serves many applications across various industries, showcasing its versatility and reliability.

Prototyping

Prototyping benefits significantly from HP’s advanced technology. Designers can quickly create functional prototypes, allowing for faster iterations and reduced lead times. High precision in printing ensures that prototypes closely match the final product. Businesses often test designs with different materials, enhancing their understanding of functionality and aesthetics. Rapid prototyping capabilities accelerate product development cycles, giving companies a competitive edge. This speed in prototyping fosters innovation, empowering teams to experiment and refine ideas more effectively than traditional methods.

Manufacturing

Manufacturing applications leverage HP’s Multi Jet Fusion technology for efficient production. Functional parts are created faster and at lower costs, meeting high demand without sacrificing quality. Customization becomes achievable, enabling manufacturers to produce unique items tailored to specific customer needs. Consistency in material properties leads to reliable performance across various applications. Additionally, reduced waste during production aligns with sustainable practices, appealing to environmentally conscious businesses. HP 3D printing strengthens supply chains by minimizing inventory needs, further streamlining operations and enhancing overall efficiency.

Advantages of HP 3D Printing

HP 3D printing offers numerous advantages that enhance the design and manufacturing process across various industries.

Cost Efficiency

Cost efficiency stands out as a key benefit of HP 3D printing technology. This method significantly reduces production costs through lowered material waste and streamlined processes. Multi Jet Fusion minimizes the need for extensive tooling and setup, allowing for shorter production runs. Businesses save money by producing parts on demand rather than maintaining large inventories. According to HP, organizations can experience up to 50% savings compared to traditional manufacturing methods. Enhanced material usage further contributes to overall cost reduction, ensuring that businesses can allocate resources more effectively and improve profit margins.

Customization Capabilities

Customization capabilities play an essential role in HP 3D printing’s appeal. This technology enables designers to create tailor-made products that meet specific client requirements. Versatility in material selection facilitates the production of unique items suited for various applications, from healthcare to automotive components. Companies can easily modify designs in response to feedback, accelerating the innovation cycle. Rapid prototyping encourages experimentation, allowing businesses to refine their products efficiently. Customization not only meets customer needs but also fosters brand loyalty by delivering personalized solutions that stand out in the market.

Challenges of HP 3D Printing

HP 3D printing faces several challenges that impact its adoption and effectiveness in various industries.

Material Limitations

Material limitations pose a significant challenge in HP 3D printing. While Multi Jet Fusion supports a range of materials, including nylon and thermoplastics, not all materials yield optimal results. Certain applications require specific characteristics like heat resistance or rigidity, which may not be fully achievable with available options. Users often encounter difficulty when seeking suitable materials for specialized applications, limiting design flexibility. Moreover, the performance consistency of materials can vary, affecting the reliability of printed parts. Manufacturers frequently express a desire for more diverse material options to broaden their production capabilities.

Market Competition

Market competition in 3D printing intensifies regularly. Numerous companies invest heavily in additive manufacturing, pushing for innovative technologies and solutions. Rival firms often introduce advanced materials and techniques that challenge HP’s market position. Cost competitiveness also remains a factor, with some competitors offering cheaper alternatives that attract cost-conscious businesses. Furthermore, industry leaders target niche markets, focusing on specialized applications that can detract from HP’s core strengths. Companies must consistently innovate and adapt to maintain their competitive edge in this rapidly evolving landscape.

Future of HP 3D Printing

HP 3D printing stands at the forefront of additive manufacturing innovation, promising advancements that will reshape multiple industries.

Innovations on the Horizon

Emerging technologies, particularly in AI and machine learning, are set to enhance HP’s 3D printing capabilities. Improved algorithms will optimize print parameters, reducing time while increasing component reliability. Enhanced software solutions might enable better material utilization, pushing the boundaries of existing applications. Novel materials capable of withstanding extreme conditions could become available, expanding functionality and usage scenarios. In addition, advancements in Multi Jet Fusion technology aim to deliver superior surface finishes and more intricate designs. These innovations will likely enhance the customization and personalization of products across various sectors.

Market Trends

Growing demand for customized production fuels the expansion of HP 3D printing. Many manufacturers seek to reduce inventory costs and adopt on-demand production methods. Industries ranging from automotive to healthcare increasingly recognize the value of rapid prototyping. Sustainability concerns also influence market dynamics, leading companies to prioritize waste reduction through additive manufacturing. As competition intensifies, HP faces pressure to maintain innovation momentum. Partnerships with material producers could facilitate access to new resources and improve overall performance. The evolution of supply chains will likely emphasize agile production capabilities powered by HP 3D technologies.

HP 3D printing is redefining the landscape of manufacturing and design. Its ability to deliver speed precision and customization positions it as a vital resource for businesses aiming to innovate. As industries continue to evolve the demand for tailored solutions will only grow.

HP’s commitment to research and development ensures that it remains at the forefront of this competitive field. With advancements in technology and materials the future of HP 3D printing promises even greater capabilities. Companies embracing this technology can expect to enhance their operational efficiency while fostering creativity and sustainability in their production processes.